Printed Circuit Board (PCB)

Omram Electronics Corp > Products > Printed Circuit Board

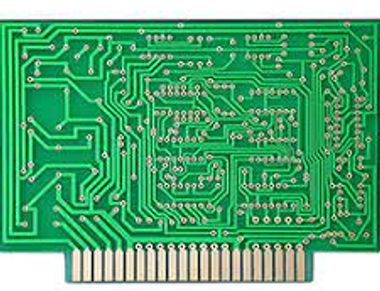

- Bare PCB or empty PCB, is an electronic board laminated in layers made from epoxy fiberglass, copper foil, and PCB inks. A blank printed circuit board has a substrate sheet, copper traces, non-conductive prepreg or polymer layers between the copper traces, and solder masks . A bare board PCB refers to a printed circuit board that is devoid of through-holes or electronic components. Empty as it usually is, it is regarded as the skeleton of the conventional PCB, before it becomes modified with through holes or electronic components.

Sub Categories

Single-Sided PCBs

Single-Sided PCBs

Single-Sided PCBs

Single sided printed circuit boards are circuit boards with one layer of conducting material on one side of the board, while the other side is used for incorporating different electronic components. A single sided board is made of a substrate layer, a conductive metal layer and followed by a protective solder mask and silk screen. Single sided circuit boards were the first printed circuit board technology and have been in circulation since the 1950s, and remain one of the most commonly used circuit boards due to their simple design.

Double-Sided PCBs

Single-Sided PCBs

Single-Sided PCBs

Double sided PCBs are a popular choice in the industry when it comes to printed circuit boards, as they allow for more complex designs, circuits and thus benefits for products. Unlike single sided PCBs, double sided PCBs can mount the conductive copper and components on both sides of the board, as opposed to just the one. These double sided boards allow for closer routing traces as they can alternate between the top and bottom layers using vias. This can be very useful in many electronic products as the circuits on one side of the board can be connected to the other with the help of holes drilled onto the board.

Multilayer PCBs

Single-Sided PCBs

Multilayer PCBs

Many printed circuit boards have one or two conductive layers, being built on either a double-sided or a single-sided substrate. A multi-layer PCB is designed and manufactured using several layers of base material. Generally speaking, any board featuring at least three conductive layers is included in this category. Multilayer PCBs are constructed using a ‘sandwich’ model, featuring numerous double-sided conductive layers separated by a corresponding number of insulating material sheets. These must all be bonded and laminated together under high pressures and temperatures, such that no air gaps remain and the final PCB assembly is sufficiently robust.

Rigid PCBs

Rigid PCBs

Multilayer PCBs

A rigid circuit board is the most traditional form of board in the PCB world. They remain hugely popular today and are used in many products consumers use daily. Rigid PCBs are a form of circuit board which are solid and inflexible in their structure and therefore cannot be bent or flexed. They’re made up of several different layers, such as a substrate layer, a copper layer, a solder mask layer and a silk screen layer, which are joined together via adhesive and heat. Whilst some circuit boards are only single sided, double sided or multilayered, rigid PCBs can take any of these forms depending on the requirements needed. However, once they have been manufactured they cannot be modified or changed.

Flex PCBs

Rigid PCBs

Flex PCBs

So what is a flexible PCB, and how do we know whether it’s right for you and your next project? When it comes to flexible PCBs, also known as ‘flex PCBs’ or ‘flex circuits’, the main differentiating point is that the electronic devices are mounted onto flexible plastic substrates. Instead of building a device in which the components must comply to the size of the circuit board, flex PCBs are instead designed to fit the device or product. Flex PCBs are usually thin, lightweight and can work exceptionally well in small spaces and in contoured shapes, which can be a challenge for other printed circuit boards. When it comes to deciding on the perfect PCB for your next product, there are several options available, from single- and double-sided, to multilayer and flex PCBs. Finding the right option that works for you and your latest innovation is important.

OMRAM Electronics Corporation

Mumbai, Maharashtra 401 305, India | E-mail: info@omram-ele.com

OMRAM Electronics Corporation, 2020 - 2025 | All Rights Reserved.

Powered by OMRAM